GOOD CYCLE BUILDING 001 Asanuma Corporation Nagoya Branch Office Renovation by Nori Architects and Asanuma Corporation

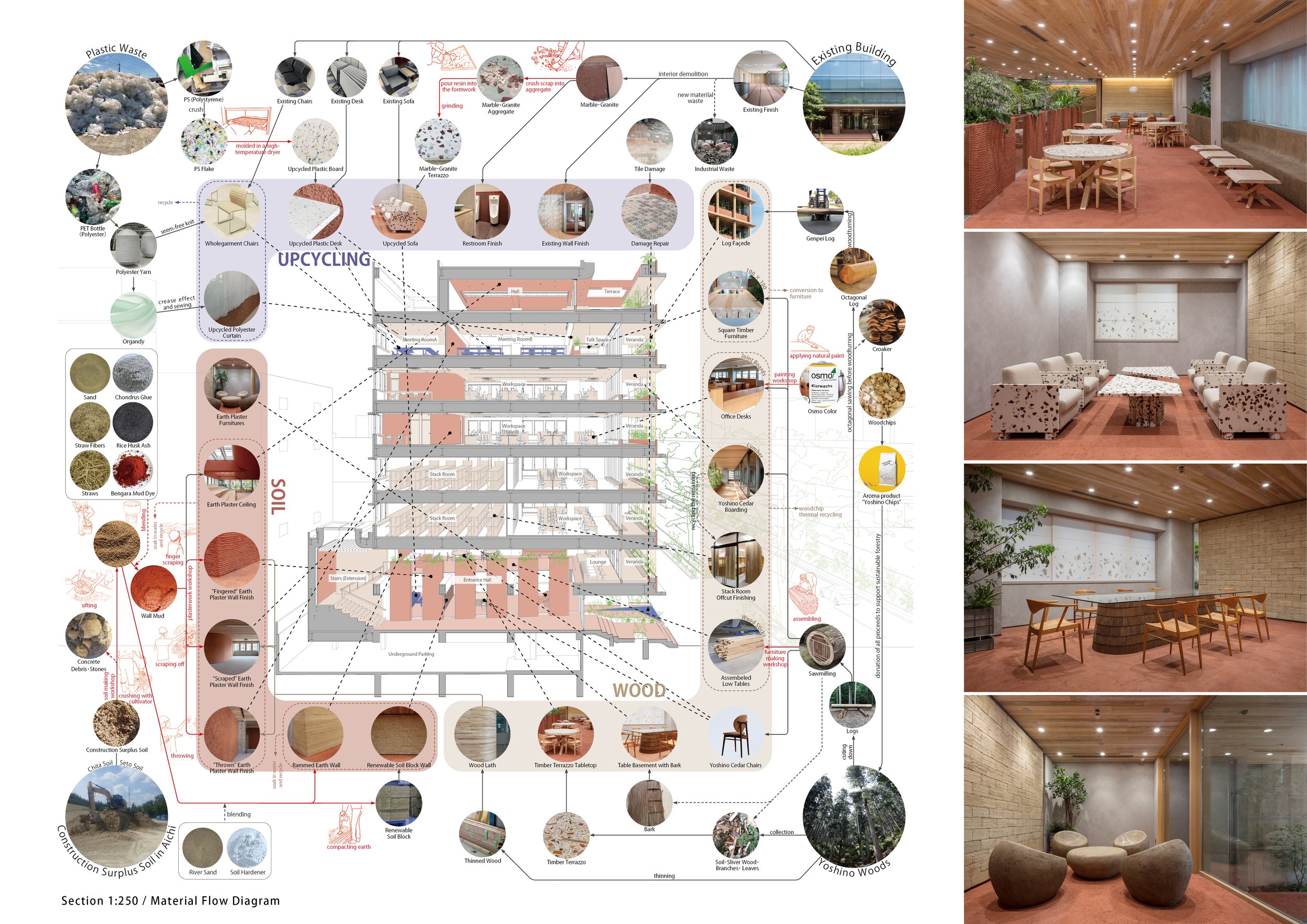

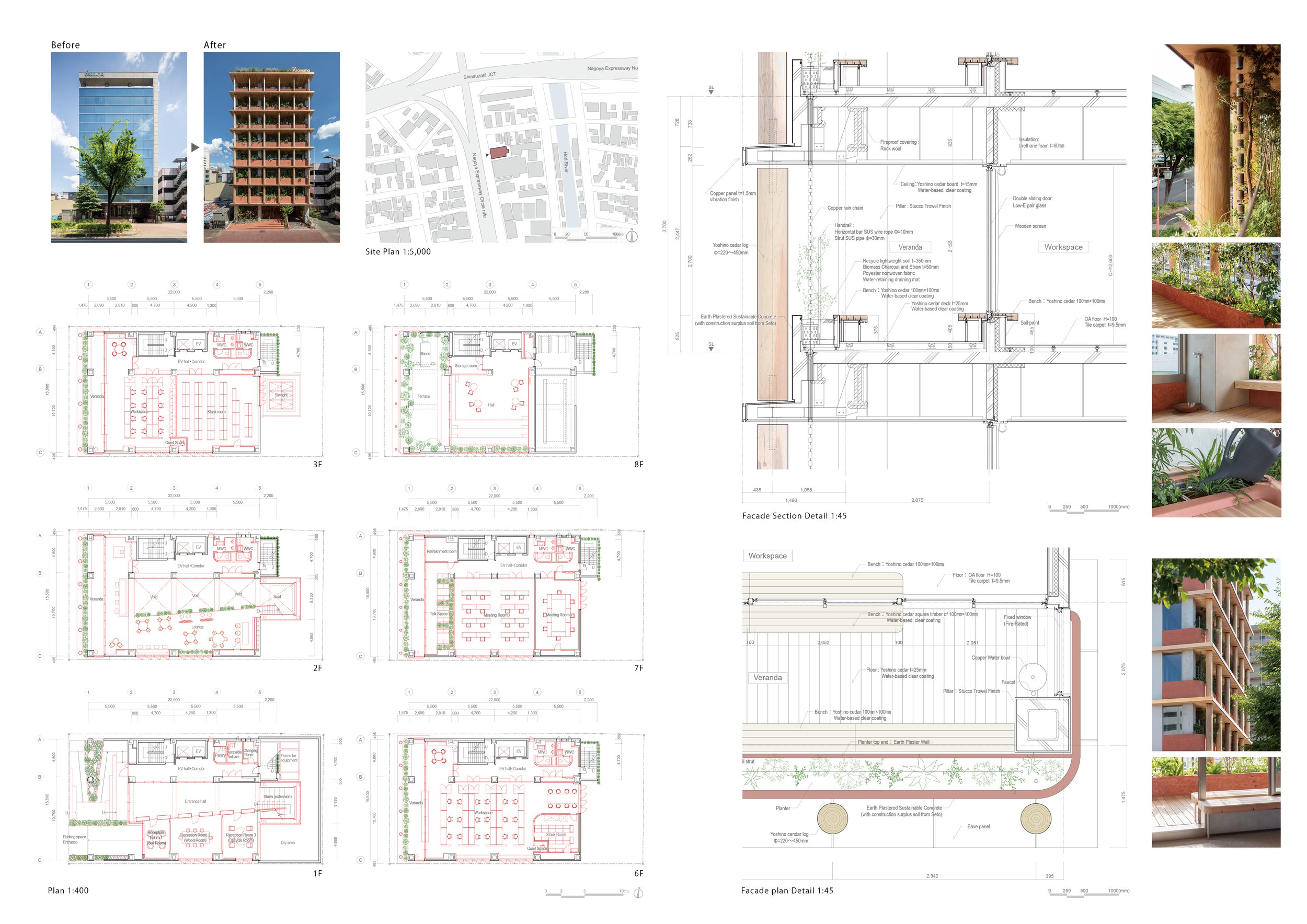

The Asanuma Corporation is promoting its first flagship project, the GOOD CYCLE BUILDING, a project to renovate a 30-year-old building into an environmentally friendly building. The existing building frame was utilized and modified to increase accessibility to natural light and wind, and new materials were added as much as possible using natural materials such as earth and wood, enabling the building users to participate in the construction and maintenance process.

The Asanuma Corporation is promoting its first flagship project, the GOOD CYCLE BUILDING, a project to renovate a 30-year-old building into an environmentally friendly building. The existing building frame was utilized and modified to increase accessibility to natural light and wind, and new materials were added as much as possible using natural materials such as earth and wood, enabling the building users to participate in the construction and maintenance process.

Inside and outside the building, soil materials were used for floors, walls, ceilings, and furniture. Raw materials were obtained from leftover soil in Aichi Prefecture. As long as amateurs participate in the finishing process, such as making marks with their fingers or throwing soil, the wall will be expressed "naturally" through human movement. Aside from the fact that earthen walls are not impure (petroleum-derived materials and cement are sometimes added to improve durability), they can also be applied for painting in the future and eventually returned to nature. In addition to the interior and exterior of the building as well as for furniture, fittings, and products, Japanese cedar from the Yoshino forest in Nara, which Asanuma Corporation manages sustainably, wharvested.ed. To minimize the amount of scrap wood generated, the front façade is built from Yoshino cedar logs with the largest diameter from a single tree. Existing stones and other materials used in existing buildings were repurposed as interior surfaces. Others were crushed into small pieces and hardened with plaster to be used as furniture surfaces. Urban waste was also used as a resource. A surface material made of waste plastic flakes that have been crushed and hardened by heating has been used to cover existing furniture, and a knitted fabric made of recycled polyester yarn has been used to wrap existing furniture.

A building functions as a "material bank" and is a transit point in the flow of materials. To maximize the possibility of re-using materials, it is imperative to use natural materials in a way that allows them to be separated from artificial materials, in order to maximize their effectiveness, and eventually return them to the earth. It is necessary to process existing man-made materials so that new materials can be created, making the most of their characteristics. By creating a delightful environment connected to the changing nature of light, wind, soil, trees, and plants, this project attempts to reconstruct buildings as part of the new material flow in the city, and to reposition architecture in a cycle that is good for people and the earth.

Planning & Drawing

Designer Profile

Norihisa KAWASHIMA

Principal at Nori Architects, Senior Assistant Professor at Meiji University

Registered Architect, JAPAN, Dr. Eng.

Born in Kanagawa prefecture in 1982, Kawashima graduated from the University of Tokyo in 2005, earned his master’ s degree from the University of Tokyo Graduate School in 2007, after which he was hired by Nikken Sekkei. Kawashima became a visiting scholar at University of California, Berkeley and worked with Prof. Dana Buntrock and LOISOS + UBBELOHDE in 2012. In 2014, Kawashima became an assistant professor at the Department of Architecture of Tokyo Institute of Technology. In 2016, Kawashima earned a doctor’s degree from the University of Tokyo Graduate School. In 2017, Kawashima established Nori Architects. In 2020, Kawashima became a senior assistant professor at Meiji University. Now Kawashima is a principal of Nori Architects and a principal of Regional Design Laboratory at Meiji University.

Representative works:Sony City Osaki [2011] , Diagonal Boxes [2016] , Yuji Yoshida Gallery / House [2017] , Saw-tooth Roofs in Ichinomiya[2017], REVZO Toranomon [2020] ,and GOOD CYCLE BUILDING 001 Asanuma Corporation Nagoya Branch Office Renovation[2021].

Representative awards: The Prize of Architectural Institute of Japan [Architectural Design], 1st Prize in the 7th Sustainable Housing Award from IBEC, 1st Prize in JIA Sustainable Architecture Award 2020, Good Design Award 2021 Good Design Best 100, Sky Design Awards 2021 THE NEW BLACK BRONZE and many others.

Kamitopen Co. Ltd. has designed the finest architecture skills throughout history - the KAMA-ASA Shop

What should the shop do to stand out from its competitors and showcase its unique craftsmanship in Tokyo Japan? Kamitopen Co., Ltd Japan's head designer and architect, Mr. Masahiro Yoshida, has re-designed the shop and using a simple shape and the delicate touches of the craftsman.

The Kappabashi area of Tokyo, Japan is a well known area for chefs and for those who love to cook, it is often referred to as "Tokyo's Kitchen Town.". A day spent walking through Kappabashi, Tokyo's "kitchen town," could easily be spent. Kappabashi is about 800 meters long, with about 170 specialty stores lining an 800 meter stretch of a street called Kappabashi Dougu Street, between Asakusa and Ueno area.

"KAMA-ASA" in Asakusa Kappabashi was established in 1908 by Minosuke Kumazawa. It was initially known as Kumazawa Imono Ten, but was changed to its current name, Kama-ASA. Over a century ago, Kama-Asa began to cater to the needs of chefs. Daisuke Kumazawa, who is the fourth generation owner of the company, has inherited the business and its vision. He aims to provide customers with quality tools that are well-designed. What should the shop do to stand out from its competitors and showcase its unique craftsmanship? Using a simple shape and the delicate touches of the craftsman, Kamitopen Co., Ltd Japan's head designer and architect, Mr. Masahiro Yoshida, has re-designed the shop.

A steel rebar, which is also called ribs and joints, is a roll of steel in the form of a stick used to build homes, buildings, and other structures.

Mashairo Yoshida of the KAMA-ASA Shop understands that the philosophy of the company is based on the belief that the finest tools are made with the right intentions, thus offering the finest skills of craftsmen who make kitchen utensils to their customers.

This is why in this store's space we felt it was appropriate to display an exhibition of the architecture skills that have been displayed by craftsmen throughout history. A particular design used rebar as the main design element, despite the fact that it is usually hidden in the walls since it is usually hidden in the ceiling. The use of rebar raised the level of sophistication in the shop dramatically.

The project won the silver award in the interior design division of Sky Design Awards www.skydesignawards.com in 2021.

Drawing/ Planning

Designer Profiles

Representative director / First Class Architect

1977 : Born in Osaka, Japan

2001 : Graduated from department of architecture,Kyoto Institute of Technology “Waro Kishi laboratory”

2001 : TAKARA SPACE DESIGN

2008 : Established KAMITOPEN architects